What if we could predict base infrastructure equipment failure before it happens?

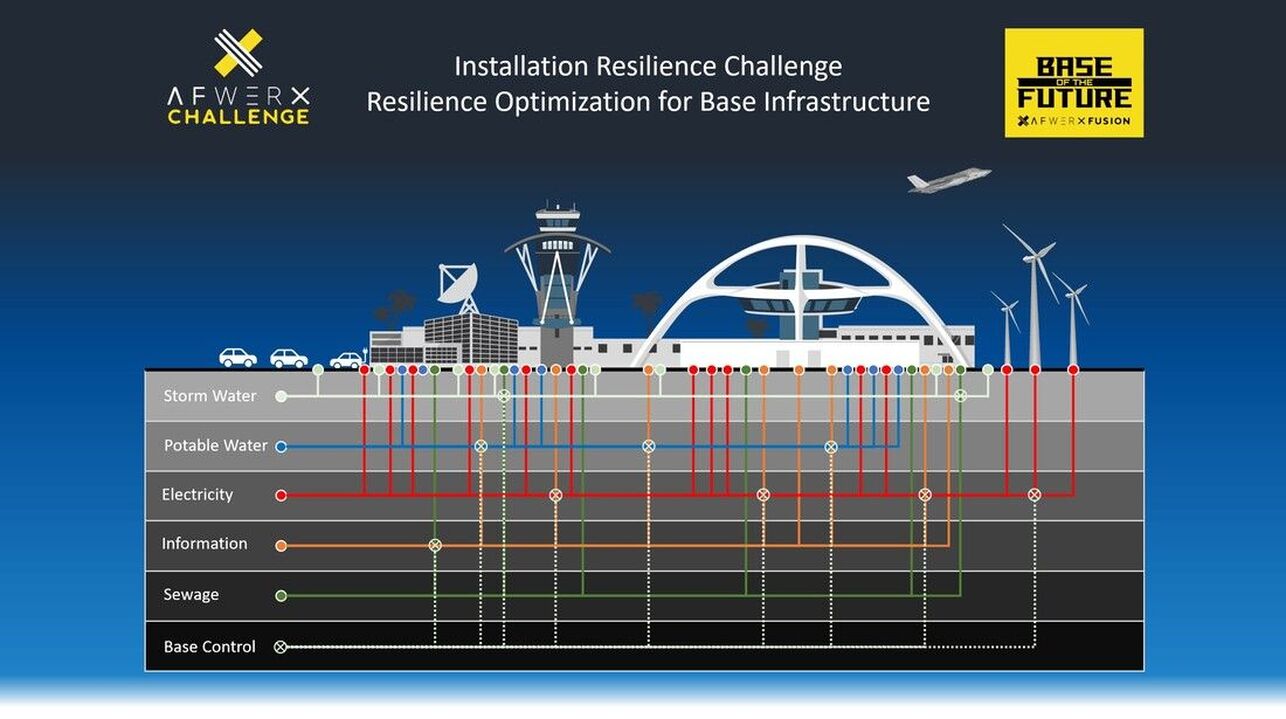

Base infrastructure for water, sewage, electricity and information distribution is a lot like a person’s digestive, nervous, and cognitive systems: no one gives them a second thought until they don’t work! By integrating Virtual Sensor Networks (VSNs) and graph models optimized with Ant Colony Optimization (ACO) into the Base of the Future’s design and operation, we can increase operational resilience and mission effectiveness throughout the facility lifecycle.

Watch the video below to learn about the technology behind our installation resistance project.

|

|

Virtual sensors are AI models of physical systems. When a physical sensor fails or using a physical sensor is impractical, virtual sensors can provide the same functionality. In cases where both physical and virtual sensors can be deployed simultaneously, we can compare divergence over time to predict outcomes before they happen. Unlike a simple computer model, virtual sensors “know what they don’t know”--they can determine if they are qualified to provide system measurements or should indicate they are out of calibration with the current situation. When connected into a VSN, their capability increases exponentially and can capture the interactions between individual elements of complex systems.

Graph-based network models can represent pedestrian and vehicle traffic, water distribution, sewage flow, electrical grid activity, and information networks equally well. ACO (Ant Colony Optimization) is an efficient way of optimizing these graph networks. Not only can ACO produce designs that balance cost, capability, and resilience simultaneously, but they also can coordinate multiple graph-represented systems. This makes it possible to simultaneously optimize water and sewer networks so that both have maximum resilience but also match capacities and flow rates. Electrical and information networks can also be simultaneously optimized to provide coordinated capabilities well. Deployed together, ACO-optimized graph models can link to real-time VSN measurements. The information from the VSN populates the graph models the ACO optimizes, then optimized operations are verified by VSNs operating in real-time. When disaster strikes, the coordinated systems can provide maximum capability with whatever infrastructure remains while also prioritizing which repairs will restore capability most quickly.

During the initial facility design process, we can maximize installation resilience and capability while minimizing operational costs simultaneously. When periodic redesign activities are needed, the graph models become the institutional memory of why the initial design was appropriate and can evaluate how proposed changes will affect resilience, cost, and complexity before they are implemented.

During its operational life, the base's VSN can monitor performance and provide information into the graph network models representing the base’s infrastructure. Normal operations can be continuously optimized, the effects of planned maintenance outages can be forecast, and unexpected disruptions can be handled effectively. Degradation of equipment due to normal wear out or unexpected damaging events can be determined by comparing VSN predictions with parallel physical measurements. For instance, a virtual sensor predicting the vibration of an electric generator in a base’s wind turbine or water pump for a base’s wells can be compared to a physical sensor measurement. When they diverge, the equipment is wearing out and the rate of divergence over time tells us how much time remains to take action.

The ACO-optimized network models can then tell us what will happen in the broader base operations when that piece of equipment fails – before it happens.

During its operational life, the base's VSN can monitor performance and provide information into the graph network models representing the base’s infrastructure. Normal operations can be continuously optimized, the effects of planned maintenance outages can be forecast, and unexpected disruptions can be handled effectively. Degradation of equipment due to normal wear out or unexpected damaging events can be determined by comparing VSN predictions with parallel physical measurements. For instance, a virtual sensor predicting the vibration of an electric generator in a base’s wind turbine or water pump for a base’s wells can be compared to a physical sensor measurement. When they diverge, the equipment is wearing out and the rate of divergence over time tells us how much time remains to take action.

The ACO-optimized network models can then tell us what will happen in the broader base operations when that piece of equipment fails – before it happens.

Watch the video below to learn about the technology behind our installation resistance project.

|

|

Virtual sensors are AI models of physical systems. When a physical sensor fails or using a physical sensor is impractical, virtual sensors can provide the same functionality. In cases where both physical and virtual sensors can be deployed simultaneously, we can compare divergence over time to predict outcomes before they happen. Unlike a simple computer model, virtual sensors “know what they don’t know”--they can determine if they are qualified to provide system measurements or should indicate they are out of calibration with the current situation. When connected into a VSN, their capability increases exponentially and can capture the interactions between individual elements of complex systems.

Graph-based network models can represent pedestrian and vehicle traffic, water distribution, sewage flow, electrical grid activity, and information networks equally well. ACO (Ant Colony Optimization) is an efficient way of optimizing these graph networks. Not only can ACO produce designs that balance cost, capability, and resilience simultaneously, but they also can coordinate multiple graph-represented systems. This makes it possible to simultaneously optimize water and sewer networks so that both have maximum resilience but also match capacities and flow rates. Electrical and information networks can also be simultaneously optimized to provide coordinated capabilities well. Deployed together, ACO-optimized graph models can link to real-time VSN measurements. The information from the VSN populates the graph models the ACO optimizes, then optimized operations are verified by VSNs operating in real-time. When disaster strikes, the coordinated systems can provide maximum capability with whatever infrastructure remains while also prioritizing which repairs will restore capability most quickly.

During the initial facility design process, we can maximize installation resilience and capability while minimizing operational costs simultaneously. When periodic redesign activities are needed, the graph models become the institutional memory of why the initial design was appropriate and can evaluate how proposed changes will affect resilience, cost, and complexity before they are implemented.

During its operational life, the base's VSN can monitor performance and provide information into the graph network models representing the base’s infrastructure. Normal operations can be continuously optimized, the effects of planned maintenance outages can be forecast, and unexpected disruptions can be handled effectively. Degradation of equipment due to normal wear out or unexpected damaging events can be determined by comparing VSN predictions with parallel physical measurements. For instance, a virtual sensor predicting the vibration of an electric generator in a base’s wind turbine or water pump for a base’s wells can be compared to a physical sensor measurement. When they diverge, the equipment is wearing out and the rate of divergence over time tells us how much time remains to take action.

The ACO-optimized network models can then tell us what will happen in the broader base operations when that piece of equipment fails – before it happens.

During its operational life, the base's VSN can monitor performance and provide information into the graph network models representing the base’s infrastructure. Normal operations can be continuously optimized, the effects of planned maintenance outages can be forecast, and unexpected disruptions can be handled effectively. Degradation of equipment due to normal wear out or unexpected damaging events can be determined by comparing VSN predictions with parallel physical measurements. For instance, a virtual sensor predicting the vibration of an electric generator in a base’s wind turbine or water pump for a base’s wells can be compared to a physical sensor measurement. When they diverge, the equipment is wearing out and the rate of divergence over time tells us how much time remains to take action.

The ACO-optimized network models can then tell us what will happen in the broader base operations when that piece of equipment fails – before it happens.