What if we could deliver emergency supplies anywhere in the world in two hours or less?

Our Emergency Parametric Re-Entry Pod (E-PREP) project delivers this capability by combining our AI pod design optimization with additive and digital manufacturing, and mission planning with our mission planning and optimization solution.

We were recently selected by the US National Science Foundation (NSF) to submit a proposal to their America's Seed Fund program for space technologies and we're thrilled to be a finalist in the AFWERX Engage: Space Global Space Transport and Delivery Challenge, placing us in the top 8% of over 800 competing companies.

We were recently selected by the US National Science Foundation (NSF) to submit a proposal to their America's Seed Fund program for space technologies and we're thrilled to be a finalist in the AFWERX Engage: Space Global Space Transport and Delivery Challenge, placing us in the top 8% of over 800 competing companies.

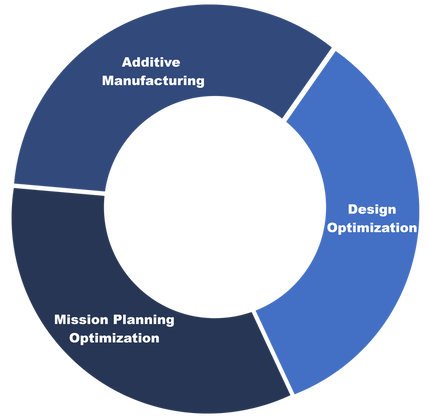

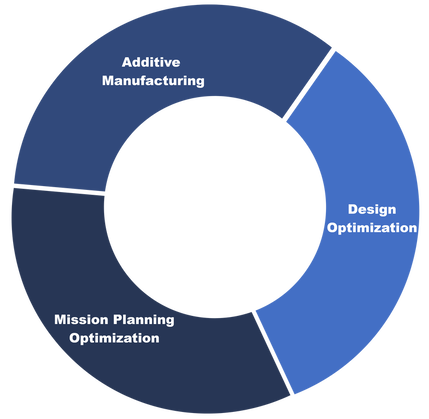

Our Emergency Parametric Re-Entry Pod (E-PREP) process consists of three key proven technologies working together to rapidly produce a delivery system for critical supplies.

Our E-PREP prototype designs are parametric. They are intrinsically stealth and can be rapidly resized to whatever shape and interior volume is required for the mission. Genetic Algorithm (GA) technology guides parametric design changes when solutions are not obvious.

Once we know the design characteristics of a specific mission’s E-PREP pod, we rapidly produce it using additive manufacturing. For “standard loadouts,” we can accelerate the process further by using additive manufacturing to produce reusable molds. This would allow us to pre-position some pods in space to drop at a moment’s notice.

Once the E-PREP pod is produced we optimize mission resources to deliver it in concert with all other in-theater activities using our proven network modeling and optimization technology. Designed from the ground up for multi-domain operations (MDO), it coordinates space, air, land, and sea resources simultaneously to deliver the best possible outcomes for endangered airmen.

What if we could deliver emergency supplies anywhere in the world in two hours or less?

Our Emergency Parametric Re-Entry Pod (E-PREP) project delivers this capability by combining our AI pod design optimization with additive and digital manufacturing, and mission planning with our mission planning and optimization solution.

We were recently selected by the US National Science Foundation (NSF) to submit a proposal to their America's Seed Fund program for space technologies and we're thrilled to be a finalist in the AFWERX Engage: Space Global Space Transport and Delivery Challenge, placing us in the top 8% of over 800 competing companies.

We were recently selected by the US National Science Foundation (NSF) to submit a proposal to their America's Seed Fund program for space technologies and we're thrilled to be a finalist in the AFWERX Engage: Space Global Space Transport and Delivery Challenge, placing us in the top 8% of over 800 competing companies.

Our Emergency Parametric Re-Entry Pod (E-PREP) process consists of three key proven technologies working together to rapidly produce a delivery system for critical supplies.

Our E-PREP prototype designs are parametric. They are intrinsically stealth and can be rapidly resized to whatever shape and interior volume is required for the mission. Genetic Algorithm (GA) technology guides parametric design changes when solutions are not obvious.

Once we know the design characteristics of a specific mission’s E-PREP pod, we rapidly produce it using additive manufacturing. For “standard loadouts,” we can accelerate the process further by using additive manufacturing to produce reusable molds. This would allow us to pre-position some pods in space to drop at a moment’s notice.

Once the E-PREP pod is produced we optimize mission resources to deliver it in concert with all other in-theater activities using our proven network modeling and optimization technology. Designed from the ground up for multi-domain operations (MDO), it coordinates space, air, land, and sea resources simultaneously to deliver the best possible outcomes for endangered airmen.

Watch the video below to learn more about the uses of and science behind E-PREP.